Versatile

Regardless whether you are in the Electronics, Connector, Fastener, Corrosion Resistance, PCB or Metal Finishing industries we have an X-Ray model to fit your specific needs.

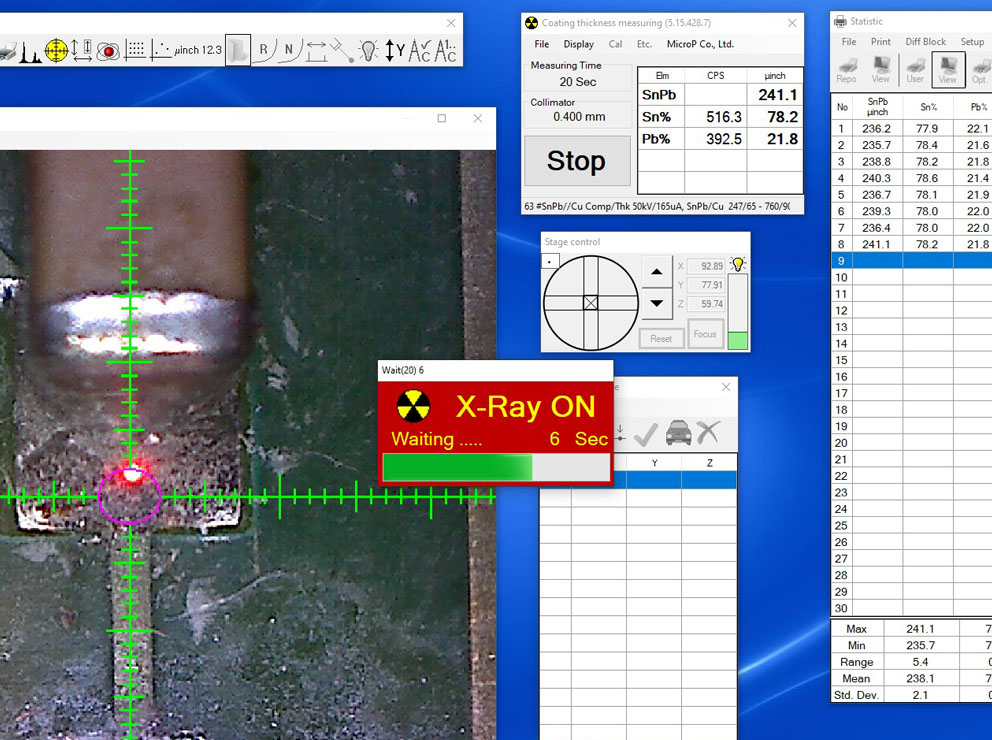

UPA Technology provides a full line of Micro Pioneer X-RAY systems for the non-destructive, non-contact plating thickness measurement and material analysis. These XRF instruments are used for confirmation of compliance to quality specifications in virtually all major industries. Our wide ranging line of XRFs are designed to measure your applications with the highest dependability. Companies around the world in the field of electroplating, automotive, electronics, metal finishing rely on these X-RAYs for their quality control. Micro Pioneer instruments are known worldwide for their accuracy, stability and advanced electronic design. The X-RAY software is user friendly, menu-driven and intuitive for use by even non-technical operators to support all aspects of operation. This enables you to focus on maintaining process quality and not on the X-Ray instrument.

Regardless whether you are in the Electronics, Connector, Fastener, Corrosion Resistance, PCB or Metal Finishing industries we have an X-Ray model to fit your specific needs.

Featuring the highest resolution color cameras and monitors to obtain the clearest video images of any XRF system on the market.

Micro Pioneer designed their electronics and X-Ray systems to last. It isn’t an accident that they have the lowest cost of annual ownership of any other brand, it is by design.

X-Ray systems increase quality, reduce waste, insure specification compliance, provide process savings and typically have a ROI in less than a year!

Our XRF tubes last practically forever! Well, almost forever. Realistically they operate at least 10….15 or possibly even 20 years between changes. Frankly, we don’t know exactly how long they will last because they so seldom fail. To be sure though, they far surpass the X-Ray tube life of other XRF systems. To substantiate our claim, we provide double the X-Ray tube warranty of any competitor. Our X-ray tube life is the best in the industry, easily surpassing the typical 3-5 year XRF tube life of other XRF brands (including Fischer, Bowman, Hitachi, Oxford, and CMI)

Some of our competitors heavily market extended warranties, even including these offers on their initial quotes, but we never do. If asked, we tell potential customers that we can quote extended warranties but, why buy an extended warranty since our systems rarely ever fail? The savings from not buying extended annual service agreements would pay for another X-Ray in only 5-6 years, so they just don’t make any sense and would be a waste of money. At least it doesn’t make sense if you have our reliable Micro Pioneer XRFs, but possibly should be considered if buying another brand.

When you call UPA, you will speak with a real person who will direct you to a product or technical specialist to answer your questions, assist with your requirements or provide applications support.